Drive Gears

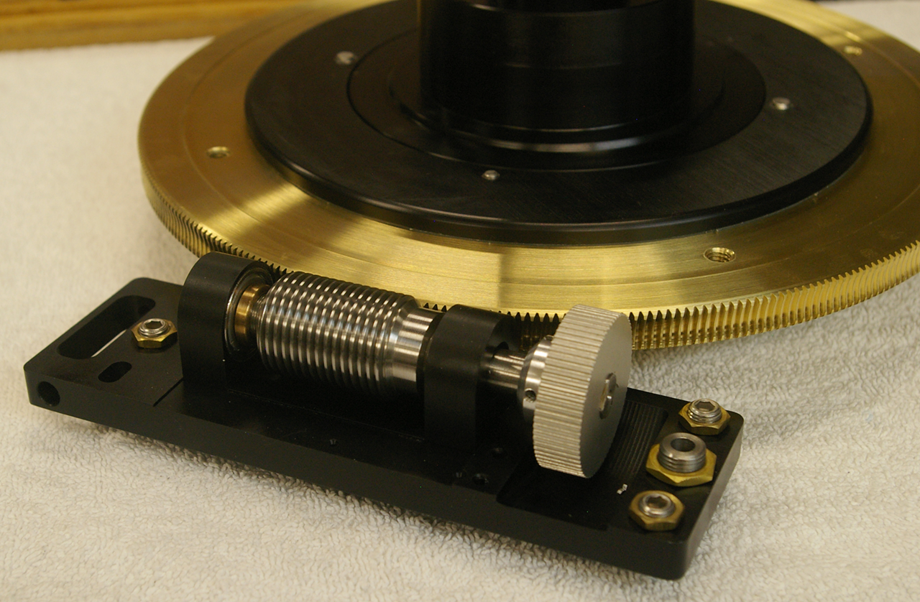

With over 32 years of experience in manufacturing telescope gears, the worm gear drives used in our mounts provide precision tracking and accurate pointing. The MI-500, MI-750, and MI-1000 mounts feature large diameter worm gear drives on both axes. Each fine pitch worm gear, made of either bronze or aluminum, is paired with a matching stainless steel worm.

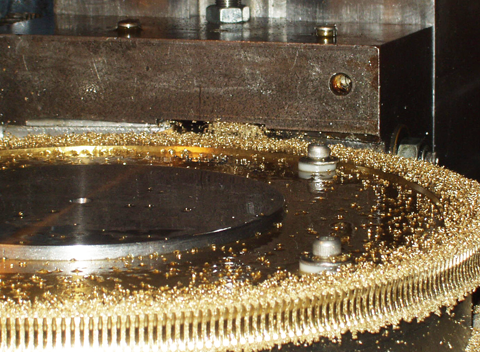

Gears are machined on special equipment designed to cut an involute tooth profile on a gear blank of specific diameter. Using special cutters known as hobs, the teeth are cut as the gear blank rotates . We use class A and AA hobs, which produce gears with a precise tooth form and accurate dimensions. Each worm is machined as a single unit to achieve accuracy of ±.0001 inches in residual run-out and thread lead error. The tracking accuracy of our drives is typically 5 arc-seconds peak to peak error.

The RA and declination axes feature a precision worm housing with sealed class 7 ball bearings. This spring loaded worm assembly pushes the worm against the worm gear, which minimize backlash in the gear train. When centering a star in the eyepiece, near zero backlash makes the telescope very responsive with little delay when changing direction. The worm assembly and servo motors are inside a protective casing, so that no motors or brackets protrude from the mount.

The MI-500F, MI-750F, and MI-1000F equatorial fork mounts use the same drive assembies as the German mounts. Since the right ascension drive tracks continuously, there is generally more wear on this axis. As an option, we offer a bronze worm gear with a stainless steel worm for the RA axis. These materials are superior to the more common aluminum worm gears one finds on most smaller commercial mounts

The bronze worm gear option is also available for the declination axes. However, unless you have special requirements, we normally recommend using an aluminum worm gear on the declination axis.

- MI-500 mount uses a 12.1-inch diameter RA drive and a 10.1-inch declination drive.

- MI-750 mount uses a 15.1-inch diameter RA drive and a 12.1-inch declination drive.

- MI-1000 mount uses a 20.1-inch diameter RA drive and a 15.1-inch declination drive.